DOUBLE BLOCK AND BLEED VALVES (DBBV)

Control Seal Double Block and Bleed dual expanding Plug Valves (DBBV) respond to the market demand for a non friction Double tight shut-off valve. Reduced space and no maintenance requirements are met. Control Seal DBBV provides 100% bubble tight sealing both up and down stream and is achieved mechanically - independent on line pressure.

SIZE: 1” ~ 48” (DN25 ~ DN1200) (up to unlimited based on approvals)

BORE: Reduced or Full (Full is piggable)

PRESSURE: 150# ~ 2500# (PN20 ~ PN420)

TEMPERATURE RANGE: -196°C ~ 250°C

CONNECTIONS: Wide choice on request

MATERIALS: Wide choice on request

DBBV is a single valve solution used as replacement of two in-line valves with a drain and/or bleed valve. Many different valve type have been used in double configuration for blocking and bleeding, sampling or draining. Traditional solutions can result in loss of product, frequent maintenance and even failure.

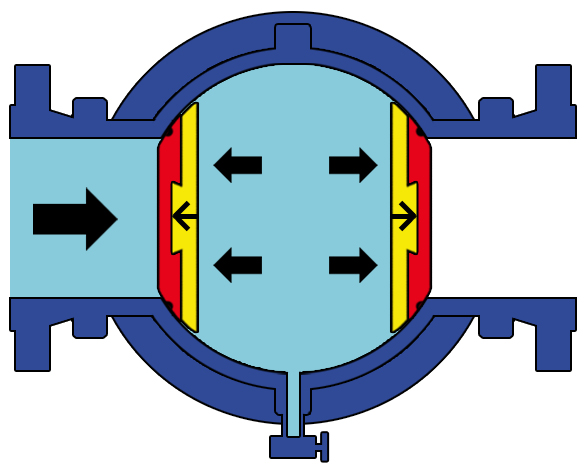

DBBV has two seated surfaces (slips). When the valve is in closed position each individual seal is fully isolating, not allowing any leakage from downstream, upstream nor from the body cavity. A thermal relief vents / bleeds the body cavity when overpressure occurs so the downstream pipeline is fully isolated from upstream pressure without necessity for pressure balancing.

Compared to other types of DBB valves, Double Block and Bleed plug Valve has the DIB - Double Isolation and Bleed function and therefore it provides double security due to two seals that are independent on each other.

The following BENEFITS arise from using SINGLE VALVE SOLUTION:

SPACE + WEIGHT REQUIREMENT REDUCTION

SHORTER DRAIN TIMES

ONE ACTUATOR INSTEAD OF TWO

CHARACTERISTICS

100% TIGHT SHUT OFF, therefore zero leakage. Provable by bleed system.

MECHANICALLY ENERGIZED SEALING without springs or other weak parts required to obtain sealing.

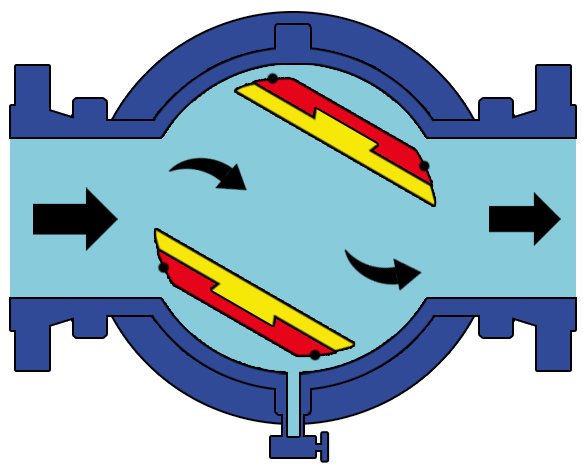

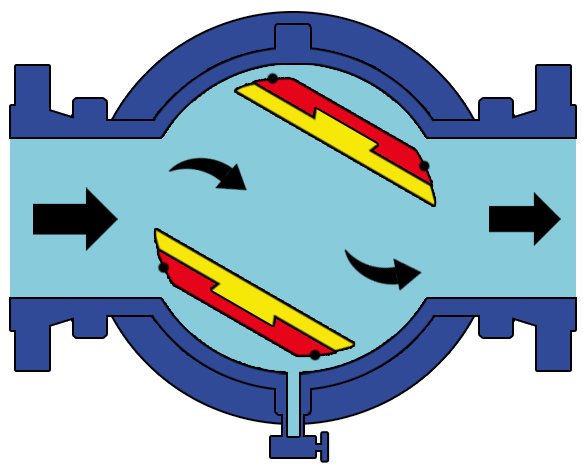

FRICTION-FREE OPENING AND CLOSING, no contact between slip seals and seating area during rotation.

NON LUBRICATED SEALING, media specific soft seal material.

DUAL EXPANDING, proven zero leakage both up and downstream.

THE SELF-LOCKING OPERATING MECHANISM on all Control Seal valves secures the closing member from rotating due to in-line forces. As a result there is no danger of line slam or shock.

APPLICATIONS

Metering skids

Tank farms

Airports

Pipelines

Manifolds

Filling lines

Control Seal has a UNIQUE DESIGN OF ITS PRODUCTS, SHORT LEAD TIME, COMPETITIVE PRICING AND EXCELLENT AFTER-SALES SUPPORT.

Control Seal has delivered the world's largest non contact Double Block and Bleed dual expanding Plug Valves - sizes 42" and 48". Full bore execution is possible for large sizes with Control Seal.

Main competitive advantage of Control Seal design is its unique invention - HELIXTRUNNION® rotating mechanism, see benefits of the design below:

SMALLER ENVELOPE due to no stem guiding groove, no stem guides as in conventional design and trunnion placed inside the valve body reducing lower plate size.

FAST OPENING AND CLOSING due to a very strong rotating mechanism.

The valve is MAINTENANCE FRIENDLY as the rotating mechanism is inside the valve. Furthermore, stemguides and gland packings are outside pressurized area and can be adjusted while the valve is in service. All valves are executed with a back seat.

Less moving parts lead to LONG LIFE AND LESS SPARE PARTS NEEDED. No stem guiding groove and stem guides as in conventional design. NO NEED OF LUBRICATION of the stem guides.

Control Seal valves have been FIRE SAFE tested by independent laboratories and have passed BS 6755 part 2, API 6FA and ISO 10497 third party wittnessed tests succesfully.

In case of system contamination resulting in the soft seals damage, it is possible to replace slips with soft seals easily by bottom or top entry while the valve is in-line and therefore REDUCE DOWNTIME of the unit/plant to minimum. No special tools are required.

All Control Seal valves are delivered with sealing specifically chosen for customer application and media in cooperation with leading experts in the field.

BLEED SYSTEMS

The functions of the bleed system: Proving tight shut off; Pressure relief inside the body cavity

The following options are available (and more on request):

|

Automatic body bleed (ABB) |

|

|

|

|

Manual Bleed Valve (MBV) |

with Gauge (MBV-G) |

|

|

|

|

Thermal Relief Upstream (TRU) |

with Gauge (TRU-G) |

|

|

|

Manual Bleed and Thermal Relief (MBTR) |

with Gauge (MBTR-G) |

|

|

|

Design |

API 6D, ASME B16.34 |

|

Face to Face dimensions |

API 6D, ASME B16.10, B16.47 |

|

Flanges |

ASME B16.5, B16.25 |

|

Fire Safe |

ISO 10497, API 6FA, BS 6755 |

|

Fugitive Emission |

ISO 15848, TÜV, Shell MESC SPE 77-312 |

|

Testing |

API 598, API6D, ISO 5208 |

|

Marking |

CE, MSS-SP-25 |

|

Topworks |

ISO 5210 |

|

1. Open Valve fully open. |

|

2. Rotating Plug (red) is rotating. |

|

3. Expanding Plug/slips have rotated 90°, the plug starts expanding the slips. |

|

4. Double Block and Bleed Valve is seated. |

|

5. Start to open Valve starts opening. The plug is moving up, retracting the slips from the body seats. Strong dovetail and stems retract the slips. |

|

6. Slips retracted Slips have been retracted prior to rotation and rotate to open position. (Further working as fig. 1 and 2 in reversed order) |